Overall Solution of Tire Retreading

1. Project Introduction

The production line is a complete set of 20-22.5-inch TBR retreading production line produced for a company in Donghai County, Jiangsu Province in the second half of 2020. The entire production line equipment covers the entire process of tire inspection, grinding, repair, brushing, glue and vulcanization, etc., with an annual production capacity of nearly 80,000 pieces.

This production line is attached to Donghai County, the dismantling and distribution center of waste trucks, and its function is perfectly combined with the needs of the local industry, which to a large extent solves the trouble of how to deal with the local waste tires, realizes the industrial value-added effect of the waste tires for the local area. And also plays a certain role in tire recycling and environmental protection. The landing of the whole production line has won the praise of customers and local industry personnel, and has received strong support from local government departments.

2. Cold Retread Process Advantage

The pre-vulcanization renovation method is also called the cold retreading method. Its process characteristics are: the use of high-pressure molded pre-vulcanized rubber tread, wrapped in a jacket vulcanization, the required temperature is much lower than the hot turning method, so a tire can be repeatedly retreading many times. A chamber tank can vulcanize multiple tires of different sizes at one time. The cold-retreading method can be used to retread both LTB and TBR tires. Cold-retreading tires are two-step vulcanized, where old and new materials are bonded firmly and do not delaminate, and the high-pressure vulcanized tread is strong and wear-resistant. The cold retreading method is currently the world's most popular tire retreading method.

①The cold-retreading tire’s tread rubber is prefabricated. The tread rubber has a high density and is more wear-resistant, prickly, puncture-resistant and cutting-resistant than hot turning.

②Cold-tread tire’s body is good quality. The tyres have longer service life. Good tread rubber has a higher service life than new tires.

③Finished tread rubber performance:

hardness (Shaoer A type) 68-72 degrees;

tensile strength 18.9-20.0MPa;

300% constant elongation stress 12.4-12.8MPa;

tearing elongation 450-470%;

Akron wear consumption 0.11cm3.

Wear resistance: 50,000 km to 60,000 km. All can meet the national standards, can be assured to choose.

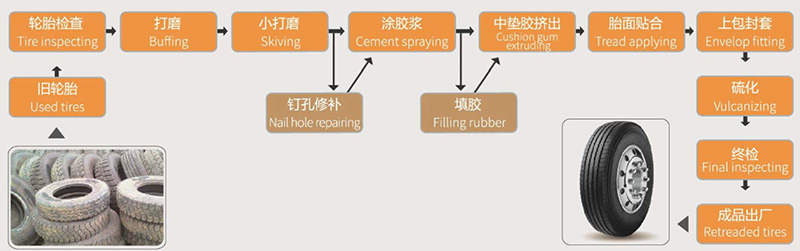

3. Flow Chart

4. Case Pictures

Retread Factory In Qingdao

Retread Factory in Shenyang

Retread Machine Export to US

Protect the natural environment and promote the development of the world circular economy.

让您的轮胎使用

物有所值,里程领先