Overall Solution of New Process Tire (New Tire)

1、 Project Introduction

TBR new process production line is the company's latest research and development of a set of new tire production and waste tire retreading production line based on the ring tread, it is also the most advanced one in China can be used for new tire production, can also be used for waste tire retreading production line, the whole line has a high degree of automation, high production fluency, good product quality stability and other advantages.Currently, the line is designed to be suitable for the production of 19.5 to 22.5 inch tires.

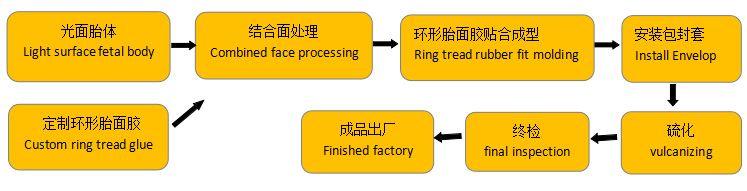

2、Flow Chart

3、Program Features

1.Subvert the traditional new tire production process. Transforming traditional tire production methods which is making Semi-finished products combined to form a single vulcanization molding turn into pre-producing smooth tires and ring treads. And use cold retread process to combine the two parts into a new tire.

2.The tire body and tread rubber are produced separately. Not only greatly improve the tire production efficiency, but also improve the performance of the tire body and tread to the maximum. Greatly improved the condition that the traditional production process needs comprehensively considering the vulcanization conditions of each part of the tire and set vulcanization parameters in a compromise.

3.New process tire plant can adopt the construction mode of central factory and satellite factory. At the same capacity, the investment cost is much lower than the traditional tire plant.

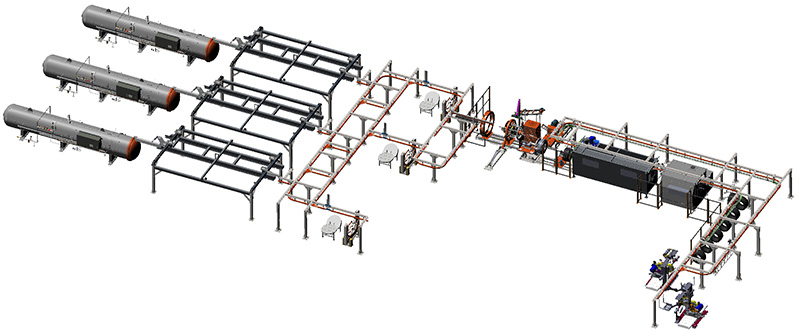

4.The whole production line realizes a highly assembly line production mode. Equipped with automatic tire conveyor system and automatic tank feeding system.

Protect the natural environment and promote the development of the world circular economy.

让您的轮胎使用

物有所值,里程领先